Quick details :

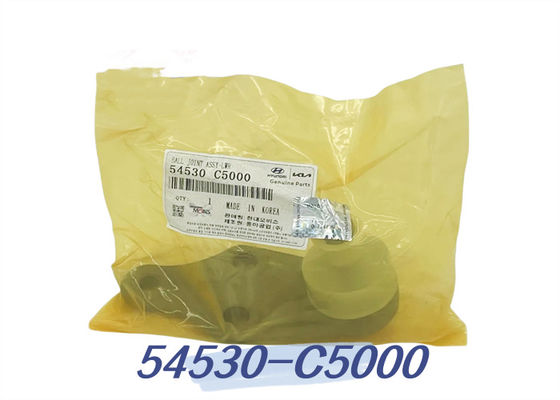

| OE Number |

54530-C5000 |

| Warranty |

1Year |

| Place of Origin |

Beijing, China |

| Car Model |

Hyundai Kia Sorento 2015 |

| Brand Name |

C&Z |

| Product name |

Lower arm ball head |

| Material |

Steel |

| MOQ |

5 Pcs |

| Application |

Hyundai Kia Sorento 2015 |

| Applicable car brand |

Hyundai Kia |

| Car model |

Hyundai Kia Sorento 2015 |

| Quality |

High-Qulity |

| Packing |

Color Box |

| DELIVERY TIME |

10-30 Days |

Product Description:

A spherical joint consists of two components: a spherical ball and a socket or housing. The ball is a perfectly round, ball-shaped structure that protrudes from one component, while the socket or housing is a cavity or cup-shaped structure that accommodates the ball. The ball is attached to a shaft or rod, while the socket or housing is affixed to another component, such as an arm or linkage. This design allows the joint to accommodate rotation in multiple axes.

The ball has a smooth, curved surface that enables it to rotate freely within the socket. This design allows the joint to accommodate movement in any direction, including rotational movement around the ball's center and angular movement in different planes.

To ensure smooth movement and reduce friction, the ball and socket are usually lubricated. This lubrication helps to minimize wear and allows for easier rotation.

Spherical joints offer many advantages such as flexibility, an extensive range of motion, and load-bearing capabilities. On the other hand, they may require periodic maintenance, including lubrication and inspection, to ensure proper functioning and to prevent excessive wear.

Lastly, it's important to note that the exact design and features of spherical joints can vary depending on the purpose and needs. Different kinds of spherical joints exist, including fixed and adjustable versions, with various load capacities and angular limits.

Features:

Rotational Freedom

Spherical joints offer rotational freedom in multiple axes. They allow for movement in a wide range of angles and planes due to their ability to rotate and articulate in various directions.

Multi-Axis Movement

Spherical joints enable movement in many directions simultaneously. Their design allows for the transfer of forces and loads while allowing rotational movement around the ball's center as well as angular movement in multiple planes.

Load-Bearing Capacity

Spherical joints can support substantial loads, making them ideal for applications with weight-bearing requirements. Their stability and structural integrity ensure that forces and loads can be distributed effectively.

Compact Size

Spherical joints are much smaller than other types of joints despite their capacity. This small size allows them to be easily integrated into mechanical systems, especially when space is limited.

Lubrication

To prevent friction and facilitate smooth movement, spherical joints often require lubricants, such as grease or oil. These lubricants are applied to the ball and socket interface, helping reduce wear and tear.

Maintenance and Adjustability

Spherical joints may offer the ability to be tightened or loosened as needed. This adjustability makes it easy to fine-tune and align mechanical systems, ensuring long-term optimal performance.

Durable Construction

Spherical joints are typically constructed with materials like steel or alloy, making them strong and resilient. These robust materials enable the joint to withstand heavy loads, vibrations, and external forces.

Sealing and Protection

Some spherical joints can be sealed to protect the internal components from contaminants. Sealing helps extend the joint's life and minimize the risk of premature wear or damage.

Versatile Applications

Spherical joints can be applied to a variety of industries, such as automotive, aerospace, robotics, and industrial machinery. In these systems, they are used in suspension systems, steering linkages, robotic arms, control systems, and several other areas due to their multi-axis movement and weight-bearing capabilities.

Technical Parameters:

Load Capacity

The load capacity of a spherical joint indicates the maximum load or force it can safely support. Generally, it is specified in terms of axial load, radial load, and moment load. It is important to ensure that the load capacity of the joint matches or exceeds the requirements of the application for proper functioning and longevity.

Angular Range

The angular range of a spherical joint indicates the maximum allowable angular movement. It is measured in terms of degrees or radians in different axes or planes. It is important to choose a joint with a suitable angular range that meets the required movement of the application.

Size/Dimensions

Spherical joints are available in a range of sizes and dimensions. These include the diameter of the ball, the outer diameter of the socket or housing, and the overall length or height of the joint. The size of the joint should allow for proper clearance and fitment within the mechanical system.

Material

Spherical joints are usually made from materials with strong physical properties, such as steel, stainless steel, aluminum alloy, or other high-strength alloys. The choice of material depends on the load capacity, environmental conditions, and specific application requirements.

Lubrication

Certain spherical joints require lubrication to reduce friction and enable smooth movement. The type of lubrication and maintenance intervals should be in accordance with the manufacturer's instructions. Proper lubrication practices are essential to maintain the performance and lifespan of the joint.

Sealing

Some spherical joints contain sealing mechanisms to protect the internal parts from contamination and moisture. These seals can be rubber seals, gaskets, or integrated sealing designs. The effectiveness of sealing impacts the durability and resistance of the joint to external factors.

Mounting Type

Spherical joints feature different mounting options, such as threaded or bolt-on connections. It is essential to choose a mounting type that is compatible with the application and allows secure attachment to the adjacent parts.

Operating Temperature Range

Spherical joints may feature specified operating temperature ranges. It is necessary to check the temperature conditions of the application and select a joint that can withstand the expected temperature range without compromising its performance or structural strength.

Applications:

| Car Fitment |

Model |

Year |

| Kia |

SORENTO |

2015-2016 |

What other you can buy from us ?

Comments :

FAQ :

Q1: Are you a manufacturer or a trading company?

A1: We're one of the largest professional manufacturers of brake discs and brake pads in China. Products cover 5,000+ brake disc part numbers, 3000+ brake pads part numbers, 96%+ car park coverage of brake discs and brake pads from A to Z for both passenger cars and commercial vehicles.

Q2: What certifications do you have?

A2: IATF16949, ISO14001, ISO45001, ECE R90, CNAS, etc.

Q3: How about your lead time?

A3: Usually, 6~8 weeks after receiving purchase orders.

Q4: Can you provide the catalogue of Winhere products?

A4: Please contact us for more info. We will reply to you as per different market.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!